JOINTING

|

Control Joints

Control joints are intentional weak spots placed in concrete to control where cracks will occur due to shrinkage during the curing process. Since concrete almost always cracks as it cures, control joints guide those cracks to occur in straight, planned lines rather than randomly across the surface.

Control joints are usually installed shortly after the concrete is placed, typically between 6 to 18 hours after finishing. The timing is critical; if you wait too long, random cracks can form before the joints are in place.

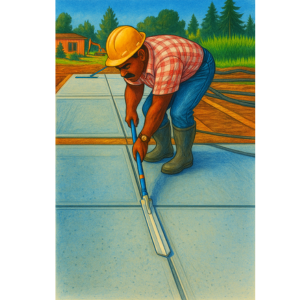

Control joints can be made by saw cutting, tooling, or using pre-formed inserts. Saw cutting using a diamond blade to cut a groove in the hardened concrete to a depth of at least one-quarter the slab’s thickness. Tooled joints are formed in the wet concrete using a jointer tool. Inserts, such as plastic strips, can also be placed in fresh concrete to create a joint line.

The spacing of control joints depends on the slab thickness, usually 24 to 30 times the thickness in inches. For example, a 4-inch slab should have joints spaced 8 to 10 feet apart. Joints should form square or nearly square panels to reduce the risk of uncontrolled cracking.

Expansion Joints (Isolation Joints): Expansion joints allow for movement caused by thermal expansion, moisture changes, or settling between separate structures or concrete elements. These joints are typically installed before the concrete is poured. They are designed to absorb expansion and contraction and prevent pressure from building up in the slab, which could lead to cracking or buckling.

Expansion joints are placed wherever a concrete slab meets a fixed object like a building, a wall, a column, or another slab. They are often made from compressible materials such as fiberboard, rubber, neoprene, or foam. In more demanding applications, expansion joints may also include dowels with sleeves to allow horizontal movement while still transferring vertical loads.

Unlike control joints, which only guide cracks, expansion joints create a full separation between elements so that each section can move independently.

Shining a light on over 80 Construction Categories, with unlimited potential for Sub Categories - Watch our Community grow!