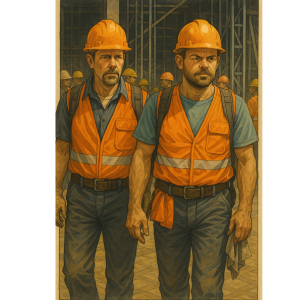

WORK GEAR

|

|||

Construction Workwear is not just Rugged Clothing—it’s a tool in itself, engineered for Safety, Performance, and Longevity on the job. Made from Heavy-Duty materials like Canvas, Ripstop, and Reinforced Denim, it resists Tearing, Abrasion, and wear over time. This is essential in environments where workers are exposed to Cutting Tools, Rough Surfaces, and Frequent Movement. Regular clothes simply can’t stand up to this kind of abuse.

Triple Stitching & Reinforcement

Garments often feature Triple-Stitched Seams. This adds a layer of Reinforcement, preventing seams from splitting under stress. Areas prone to high movement—like the crotch, shoulders, and underarms—are particularly well-reinforced to extend garment life.

Tool Pockets & Functional Design

A defining feature of workwear is its Functional Utility. including strategically placed Tool Pockets, Hammer Loops, and Utility Slots, designed to keep essential tools within reach and reduce the need for Tool Belts. Some Bibs also incorporate compartments for Phones, Fluke Testers, Driver Bits and Utility Knives.

Padded Knee Facilitation

Long hours kneeling on hard surfaces can take a serious toll on workers’ knees. That’s why many work pants are designed with Padded Knee Pockets or Knee Pad Slots, allowing workers to insert pads for extra protection.

Seasonal & Trade-Specific Variants

Modern Workwear has evolved to address Seasonal Conditions. There are now Summer Lines made from Lightweight, Breathable Fabrics that wick moisture and improve airflow, as well as Insulated Winter Gear designed to retain heat while still allowing mobility. In addition, many manufacturers now offer Trade-Specific Ranges, for Electricians, Carpenters, Plumbers, and Painters—each with custom features like Fire-Retardant Fabric (FR CLOTHING), Non-Conductive Materials, and Paint-Resistant Coatings.

Shining a light on over 80 Construction Categories, with unlimited potential for Sub Categories - Watch our Community grow!